Home

1756-A17 ControlLogix Chassis Allen-Bradley

1

/

of

3

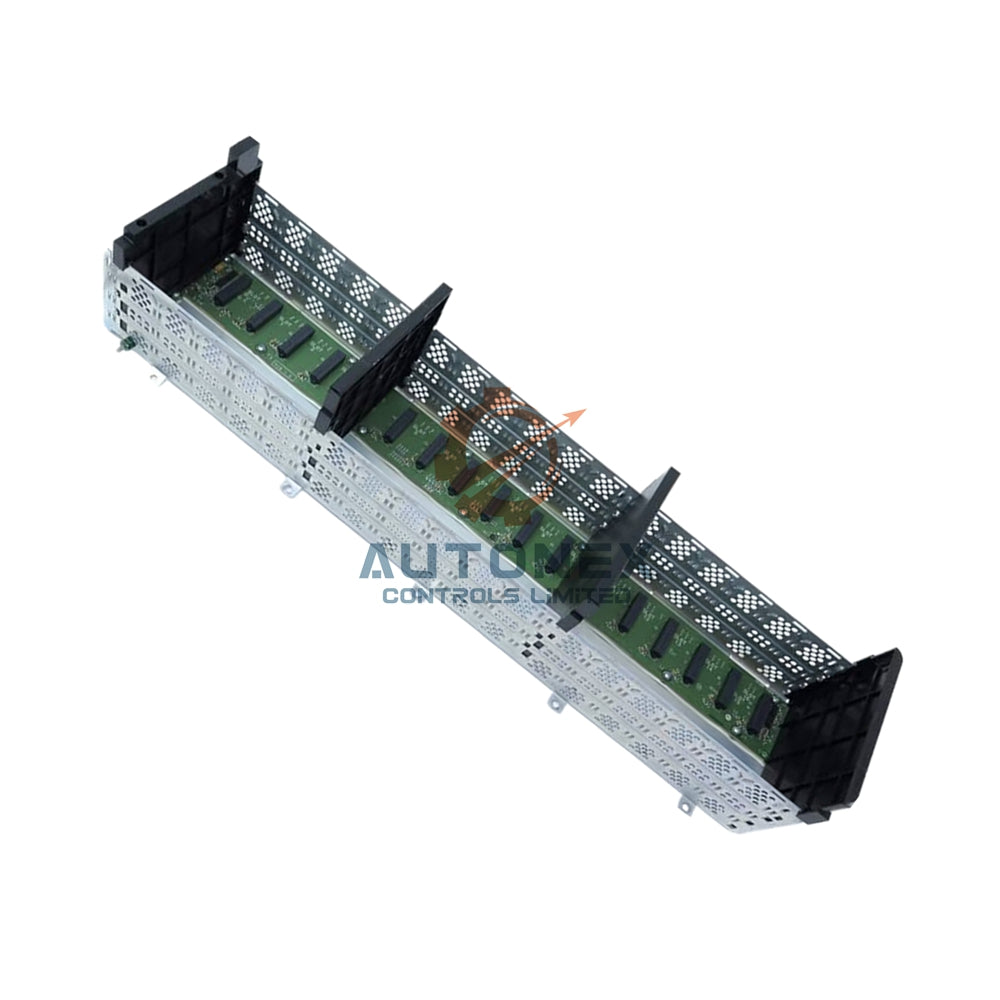

1756-A17 ControlLogix Chassis Allen-Bradley

No reviews

In stock (16 units), ready to be shipped

-

Vendor:

Allen-Bradley

-

Type:

ControlLogix Chassis

-

Country of Origin:

USA

-

Dimensions:

73.8*16.9*14.5cm

- Weight:

2200 g

- Tags: Controllogix chassis

Allen-Bradley 1756-A17 ControlLogix Chassis

Chassis Configuration & Mounting

- Maximum Slot Capacity: Seventeen total slots for extensive system expansion

- Mounting Security: Ten mounting tabs (five top, five bottom) for robust installation

- Power Supply Integration: Dedicated left-side mounting area separate from main slots

- Series Options: Available in Series A, B, and C with progressive improvements

- Series C Enhancements: Improved slot guides, ventilation, and additional grounding

Power Distribution System

- High-Capacity Backplane: 15 amps maximum at 5.1V DC for power-intensive modules

- Per-Slot Power: 6 amps maximum per slot at 5.1V DC allocation

- Comprehensive Voltage Support: 1.2V, 3.3V, 5.1V, and 24V DC distribution rails

- Thermal Management: 6W maximum power dissipation with optimized cooling

- Efficient Operation: 1.8W typical power consumption during normal operation

Physical Dimensions & Space Requirements

- Chassis Dimensions: 738 x 169 x 145 mm (29.06" x 6.65" x 5.71")

- Minimum Cabinet Size: 914 x 762 x 203 mm (36" x 30" x 8")

- Adjacent Chassis Clearance: 4.0" left side plus power supply width

- Right Side Clearance: 3.0" plus power supply width for maintenance access

- Vertical Clearance: 6.0" top and 2.0" bottom for proper ventilation

Advanced System Features

- Sequence of Event Timestamping: Built-in capabilities for critical event recording

- RIUP Support: Full Removal and Insertion Under Power functionality

- Electronic Keying: Prevents module installation and replacement errors

- Comprehensive Diagnostics: Advanced fault identification for system and field side issues

- High-Speed Communication: Optimized backplane for fast inter-module data exchange

Installation & Electrical Requirements

- Functional Earth Ground: 8.3 mm² (8 AWG) copper wire minimum

- Protective Earth Ground: 2.1 mm² (14 AWG) copper wire minimum

- Wire Specifications: 90°C (194°F) rated or higher insulation required

- Mounting Hardware: Compatible with or without SEM screws installation

- Wiring Interface: Requires Bulletin 1492 IFM or RTB for field-side connections

Compatible Power Supplies

- Standard Models: 1756-PA72, 1756-PB72

- Enhanced Models: 1756-PA75, 1756-PB75, 1756-PC75

- Specialized Models: 1756-PH75 for specific high-performance applications

- Selection Criteria: Based on total module power requirements and system redundancy needs

Application Scenarios

- Large Process Plants: Refineries, chemical processing, and power generation

- Complex Manufacturing: Automotive plants and large discrete manufacturing

- Infrastructure Systems: Water treatment facilities and transportation systems

- Mission-Critical Applications: Systems requiring maximum redundancy and reliability

- Expansion Projects: Growing automation systems requiring extensive I/O capacity

Frequently Asked Questions

What makes the 1756-A17 suitable for large-scale applications?

- The 1756-A17 provides maximum expansion capacity with 17 slots, making it ideal for complex systems requiring multiple processors, extensive I/O, and specialized communication modules.

What are the Sequence of Event capabilities?

- Built-in timestamping functionality allows precise recording of event sequences for critical process monitoring and troubleshooting.

How many mounting points does this large chassis have?

- It features ten mounting tabs (five top, five bottom) for secure installation of the extended chassis length.

What clearance is needed between adjacent chassis?

- Allow 4.0" plus power supply width on left side and 3.0" plus power supply width on right side for proper maintenance access.

What diagnostic features are included?

- Comprehensive diagnostics identify both system and field-side faults, while electronic keying prevents module installation errors.

What are the Series C improvements?

- Enhanced slot guides, improved ventilation, reinforced mounting tabs, additional mounting holes, and extra ground screw for panel termination.

What cabinet size is required?

- Minimum 36" W x 30" H x 8" D cabinet space is needed to accommodate the chassis and provide proper maintenance access.

For technical specifications and large system planning assistance, contact our automation experts at: sales@nex-auto.com

Fast & Reliable Shipping

Quick worldwide delivery

keeps your automation projects on schedule.

Genuine & Trusted

All components are 100% authentic

ensuring reliable performance for your systems.

- Express Delivery

- 12 Months Warranty

- 30 Days Easy Returns

Customer Support

Get Help When You Need It Most

Here to Assist Your Automation Needs

Contact us for pricing, product details, or order assistance — our experts are available to help.

Know Your Return Rights

You have 30 days to return a product if it doesn’t meet your requirements. See the full policy for details.