Your Essential Guide to the 1756-L73XT Controller for Tough Industrial Sites

Discover why the Allen-Bradley 1756-L73XT is the preferred PLC choice for challenging industrial settings. This article delivers expert insights into its robust features and real-world value.

Engineered for Maximum Resilience

The 1756-L73XT excels where ordinary controllers cannot. It reliably functions in extreme temperatures from -20°C to 70°C. Moreover, it endures heavy vibrations up to 5 Grms. This resilience guarantees stable operation in sectors like mining and material handling.

Guarding Against Harsh Elements

Its advanced sealed enclosure offers superior defense. When mounted correctly, it achieves a complete IP67 protection rating. Consequently, it effectively blocks dust, moisture, and chemical sprays. This makes it perfect for wet environments like food and beverage plants.

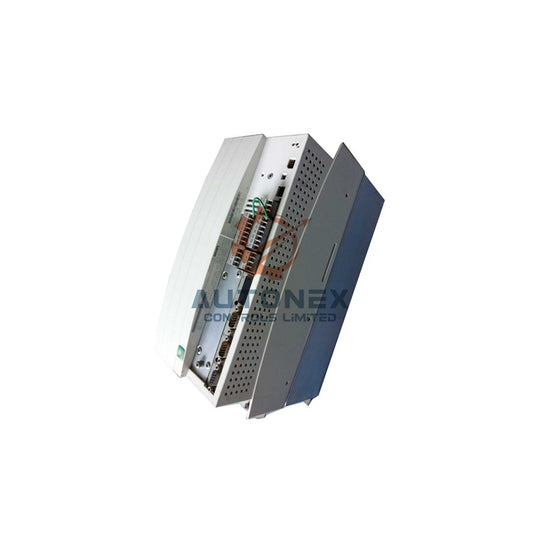

Powerful Performance for Demanding Applications

This controller provides serious computational power for complex tasks. It features a fast 1.8 GHz dual-core processor and 2 MB of user memory. Therefore, it smoothly manages advanced motion control and high-speed data acquisition. It can also support extensive networks with over 10,000 I/O points.

Meeting Global Safety Standards

This product complies with critical international certifications. It carries UL, ATEX, and IECEx approvals for use in hazardous areas. These certifications provide verified risk reduction for engineers. Importantly, the platform supports safety system designs up to SIL 3.

Boosting Operational Uptime and OEE

The XT series directly enhances long-term system reliability. Its rugged construction significantly increases the mean time between failures (MTBF). This improvement directly boosts Overall Equipment Effectiveness (OEE). Therefore, you gain more productive time and lower lifetime costs.

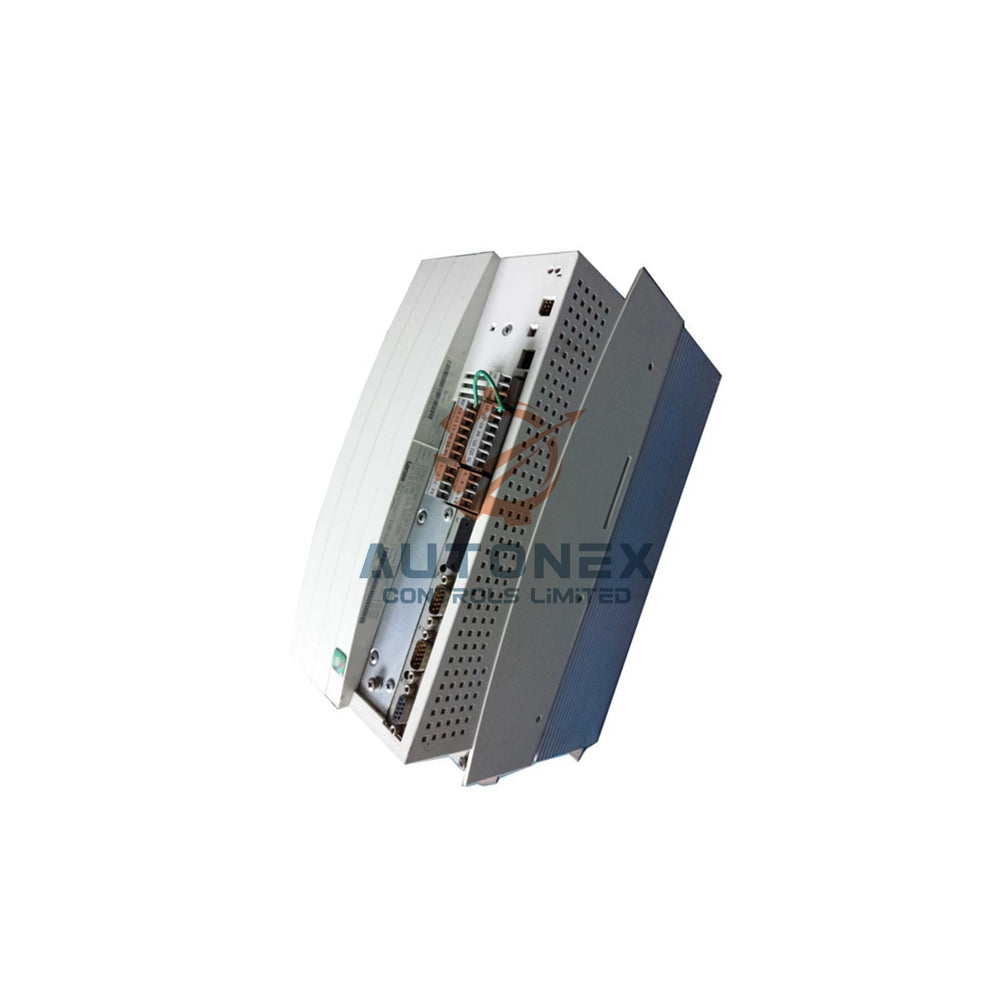

Easy Integration Saves Time and Money

This unit seamlessly connects with existing control architectures. It works natively with PlantPAx DCS and standard Logix programming software. As a result, system upgrades require minimal software changes. This compatibility protects your current automation investments effectively.

Delivering a Strong Financial Return

Investing in the 1756-L73XT prevents expensive unscheduled stops. Industry data indicates it can cut failure rates by 40% in tough conditions. Thus, the higher initial cost delivers compelling long-term savings. It also ensures consistent product quality and output.

Practical Application Scenario

Consider a mineral processing plant with constant dust and vibration. Standard PLCs here often face premature failure. However, deploying the 1756-L73XT ensures continuous control system operation. This solution minimizes costly downtime and maintenance interventions dramatically.

Expert Analysis and Commentary

The trend towards robust, "fit-and-forget" automation is clear. In my professional view, the 1756-L73XT addresses this need precisely. It represents a strategic investment, not just a component purchase. Selecting the right hardware for harsh duty is crucial for modern digital operations.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of the 1756-L73XT over a standard L7 controller?

A1: Its primary advantage is extreme environmental ruggedness. It offers superior protection against temperature, vibration, and contaminants.

Q2: Can I use my existing ControlLogix program with the L73XT?

A2: Yes, absolutely. The controller uses the same Rockwell Automation Studio 5000 software. Your program migration effort is typically very minimal.

Q3: Is this controller suitable for outdoor installations?

A3: Yes, with proper cabinet consideration, its wide temperature range and IP67 rating make it suitable for sheltered outdoor applications.

Q4: What industries commonly use the XT series?

A4: Key industries include mining, oil & gas, wastewater treatment, marine, and heavy transportation.

Q5: Does it support modern communication protocols?

A5: Yes, it supports EtherNet/IP, ControlNet, and DeviceNet. This ensures easy connectivity within modern Industrial IoT frameworks.

Contact Us for Inquiries:

Email: sales@nex-auto.com

Phone/WhatsApp: +86 153 9242 9628

Partner: NexAuto Technology Limited

Check below popular items for more information in AutoNex Controls