The Untapped Strategic Value of Legacy Automation Systems

Modern manufacturing conversations prioritize cutting-edge technology. Artificial intelligence, advanced robotics, and comprehensive IIoT networks dominate the headlines. However, this focus overlooks a crucial industrial reality. Many production lines depend on older, reliable hardware. This reliance creates a significant challenge known as the Obsolescence Dilemma. Manufacturers phase out support for components still vital to daily operations. Consequently, plant managers face costly upgrade pressures. Viewing these legacy parts as mere liabilities is a strategic error. With proper management, they become valuable assets. They ensure uptime, reduce waste, and enable a cost-effective transition towards smarter manufacturing.

Why Legacy Control Systems Remain Indispensable

Understanding the continued role of older hardware requires examining real-world constraints. Economic and operational factors justify their sustained use in modern facilities.

The True Cost of a Complete System Overhaul

Replacing an entire control system involves substantial hidden expenses. The initial hardware cost is often minimal by comparison. A full migration triggers several financial impacts. Production must halt for installation and commissioning, costing thousands per hour. Engineers must rewrite and debug decades-old PLC or DCS logic for new platforms. Moreover, operational staff need comprehensive retraining. Therefore, upgrading one machine can disrupt an entire line. Replacing a single failed module is frequently more economical. If equipment meets output goals, a full digital overhaul may offer poor ROI.

Proven Reliability in Critical Applications

In sectors like power generation or water treatment, stability is non-negotiable. The reliability engineering "bathtub curve" explains this preference. New components risk early-life failures from defects. Legacy PLCs that have operated for years are well past this infant mortality phase. Their performance is predictable and proven in specific environments. A twenty-year-old controller in a automotive plant is a known quantity. For critical infrastructure, this proven track record outweighs theoretical advantages of unproven new systems. Trust is built on documented, long-term performance.

Developing a Proactive Obsolescence Management Plan

Relying on legacy components demands a strategic, not reactive, approach. Effective management safeguards production continuity.

Shifting from Reactive to Proactive Maintenance

Waiting for a part to fail before searching for a replacement is incredibly costly. Downtime in industries like pharmaceuticals or automotive results in massive revenue loss. A superior strategy involves proactive auditing. Teams should catalog all installed base equipment and identify End-of-Life risks. Subsequently, they can secure critical spares before shortages occur. This requires partners beyond the original OEM, especially for discontinued product families. Establishing relationships with specialized distributors is crucial for supply chain resilience.

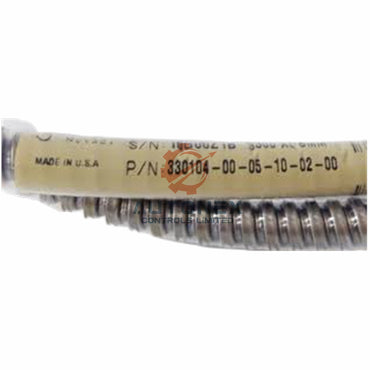

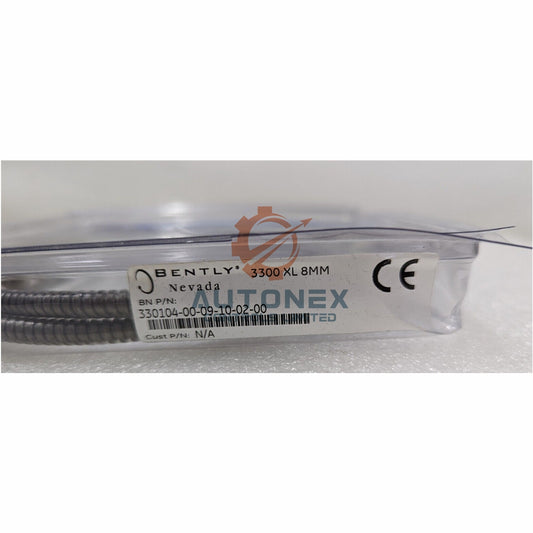

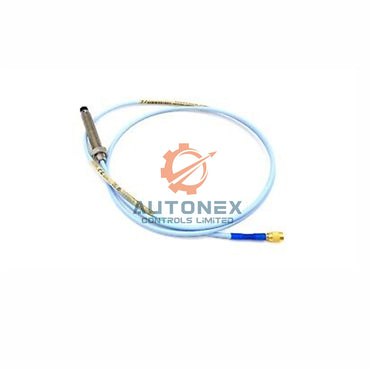

Sourcing Authentic Legacy Components

The secondary market for industrial automation parts is essential. However, sourcing requires diligent supplier vetting. Key criteria separate reliable partners from risky ones. Always verify their testing protocols; proper load and functional testing is mandatory. A strong warranty, typically 12 months, reflects confidence in part quality. Furthermore, a clear return policy is essential. Companies like NexAuto Technology Limited provide access to these verified surplus components. This ensures compatibility and reliability for your control systems.

Integrating Legacy Hardware with Industry 4.0

Maintaining old equipment does not mean rejecting innovation. Hybrid solutions effectively bridge the gap between old and new.

Retrofitting for Data Connectivity

You can modernize legacy machines without replacing core controllers. Industrial edge gateways serve as a perfect bridge. These devices connect to old serial ports like RS-485 on legacy PLCs. They then convert data to modern protocols like OPC UA or MQTT. This "wrap and extend" method extracts valuable machine performance data. Therefore, manufacturers gain insights into efficiency and predictive maintenance needs. It is a low-risk, high-value entry point into factory automation digitalization.

Supporting Sustainability Goals

Extending machinery life aligns with corporate environmental responsibility. Manufacturing new electronics consumes significant energy and resources. Discarding functional control systems contributes to global e-waste. By maintaining and repairing existing systems, companies participate in the circular economy. This practice maximizes the utility of embedded resources. It combines financial wisdom with sustainability objectives, enhancing brand reputation.

Practical Application: A Hybrid Modernization Case

Consider a bottling line from the early 2000s with legacy PLCs. The mechanical system is sound, but management wants production analytics. A full control system upgrade would be prohibitively expensive and disruptive. The solution involves installing an edge gateway on the network. This device collects data from the existing PLCs via a legacy protocol. It then streams key metrics—OEE, cycle times, motor temperatures—to a cloud dashboard. As a result, the plant gains real-time visibility without altering the reliable control logic. This project typically pays for itself within months through identified efficiency gains.

Author's Insight: A Balanced Automation Strategy

The relentless push for the "newest" technology can be a distraction. True operational excellence comes from strategic balance. Legacy systems provide stability and predictable performance that form the foundation of production. New IIoT and AI tools offer layers of optimization and insight. The most successful manufacturers intelligently blend both. They protect their core operational assets while incrementally adding digital capabilities. This phased approach manages risk and capital expenditure effectively. It respects the proven while cautiously adopting the promising.

Frequently Asked Questions (FAQ)

Q1: Is using refurbished industrial automation components reliable?

A: Yes, if sourced from certified distributors. Reputable suppliers perform rigorous testing, such as burn-in and functional validation, and provide substantial warranties, ensuring part integrity matches or exceeds OEM standards.

Q2: When should we finally upgrade a legacy control system?

A: Upgrade when the total cost of ownership (including downtime, maintenance, and scarce parts) exceeds the cost of a new system. Monitor Mean Time Between Failures (MTBF) and parts availability as key indicators.

Q3: Can legacy PLCs communicate with modern MES or SCADA software?

A: Absolutely. Using protocol converters or edge gateways, data from legacy PLCs and DCS can be integrated into modern software via OPC UA, MQTT, or REST APIs, enabling full connectivity.

Q4: Where can we find technical documentation for discontinued parts?

A: Specialized industrial automation distributors often maintain extensive archives of datasheets, manuals, and wiring diagrams for obsolete components, which are essential for troubleshooting and integration.

Q5: How does maintaining legacy systems support sustainability (ESG) goals?

A: It reduces electronic waste (e-waste) and the carbon footprint associated with manufacturing new equipment. Extending asset life is a core principle of the circular economy, aligning with environmental Social and Governance criteria.

Conclusion

Strategic manufacturing excellence is not defined by having the latest technology alone. It is achieved through a smart, balanced approach to assets. Legacy automation components deliver unmatched stability and cost-effectiveness. When managed proactively with reliable partners, they ensure continuous production. By integrating them with modern IIoT solutions, you unlock data-driven improvements. This pragmatic path secures both your present output and your future innovation potential. Audit your spare parts strategy today to protect your operations tomorrow.

For inquiries on sourcing legacy industrial automation components, control systems, or integration solutions:

Contact: sales@nex-auto.com | +86 153 9242 9628

Partner: NexAuto Technology Limited

Check below popular items for more information in AutoNex Controls