Balancing Speed and Precision: The Evolving Challenge in Industrial Automation

Across global production facilities, robotic systems increasingly handle operations demanding extreme accuracy, such as assembling micro-electronics or calibrating sensitive medical devices. This shift towards automation boosts output and ensures consistent quality. Moreover, it meets the fast turnaround demands of modern international supply networks. However, accelerating these machines introduces significant motion control complexities.

The Core Dilemma: Speed Versus Accuracy in Automation

A fundamental trade-off exists in automation engineering. Specifically, faster robot movement generates increased mechanical vibration. Consequently, this oscillation can compromise the precise positioning of the robot’s end-effector. In industries like semiconductor manufacturing, even micron-level deviations cause product defects. Traditional solutions often lower productivity. Therefore, a more intelligent approach is necessary.

Innovations in Sensing and Control Systems

Advanced sensor systems now address this challenge directly. Micro-electromechanical systems (MEMS) provide high-frequency vibration data. When engineers place these sensors near the end-effector, they capture real-time motion feedback. This data allows the Programmable Logic Controller (PLC) to make instant corrections. As a result, robots maintain high precision without sacrificing operational speed.

Enabling Adaptive and Smarter Robotics

Modern control systems leverage data from multiple sensors. This integration, supported by machine learning, enables predictive adjustments. For instance, a robot can anticipate and counteract vibration patterns. This capability allows for more flexible, high-mix production lines. Such adaptability is crucial for manufacturers navigating tight labor markets.

Practical Applications and Regional Impact

Implementing these technologies offers tangible benefits. A factory can reduce its reliance on vibration-damping equipment. This saves valuable floor space and shortens commissioning time. In practice, these advancements support national industrial strategies. Companies gain the ability to produce high-value components competitively.

Author’s Insight: The Future of Factory Automation

The pursuit of higher throughput with tighter tolerances is relentless. In my analysis, the future lies in smarter, sensor-driven control. The integration of quartz-based sensors with MEMS accelerometers represents a significant leap. Manufacturers should evaluate where direct feedback can replace indirect motor feedback. This strategic upgrade often delivers the best return on investment.

Solution Scenario: Precision Circuit Board Assembly

Consider a facility producing advanced circuit boards. A high-speed robotic arm places micro-components. By integrating a MEMS vibration sensor, the system detects subtle shakes. The PLC then adjusts the arm’s trajectory in milliseconds. This solution ensures placement accuracy within 10 microns while maintaining a faster cycle time. The result is higher yield and less rework.

FAQ Section

Q1: Why does increased speed cause inaccuracy in robots?

A1: Rapid movement creates inertia changes, inducing mechanical vibration that disturbs the tool's precise position.

Q2: How do modern sensors improve robotic precision?

A2: Sensors like MEMS placed at the end-effector provide real-time data, enabling the control system to make instant corrective adjustments.

Q3: Can older automation systems be upgraded for better speed-precision balance?

A3: Yes, often by retrofitting advanced sensor packages and updating the PLC or motion controller software.

Q4: What industries benefit most from these advancements?

A4: Precision electronics, medical device manufacturing, and any sector where micron-level accuracy is critical.

Q5: How does this technology affect factory floor efficiency?

A5: It reduces the need for bulky damping equipment and constant recalibration, saving space and time.

Partner: NexAuto Technology Limited : https://www.nex-auto.com/

Contact Information Inquiries:

Email: sales@nex-auto.com

Phone: +86 153 9242 9628

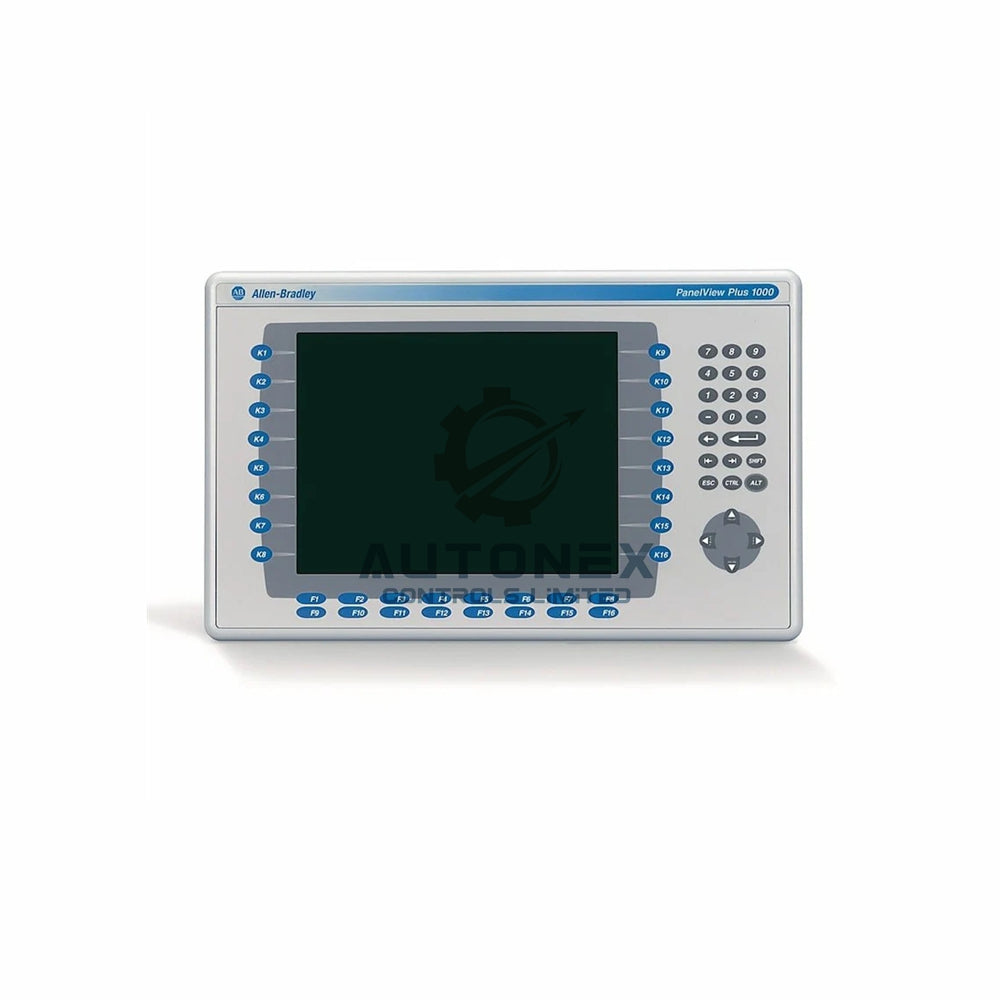

Check below popular items for more information in AutoNex Controls