Beranda

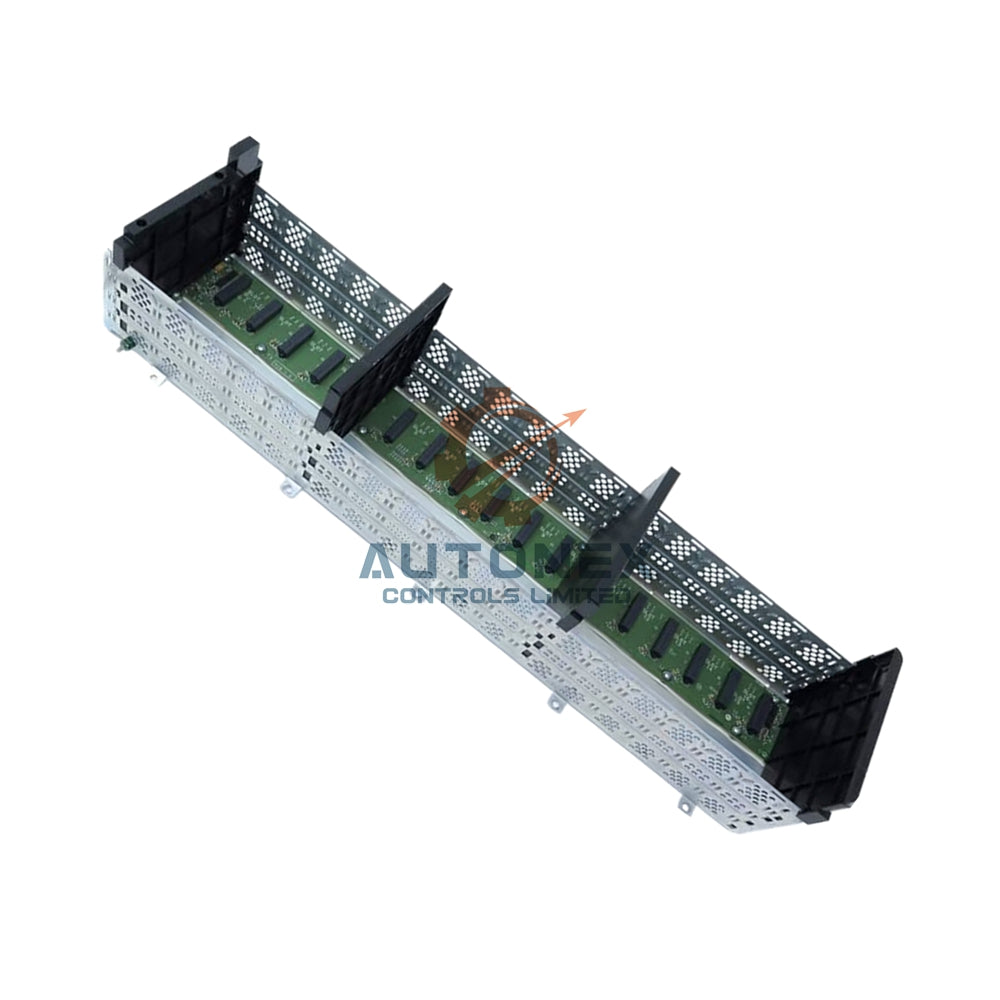

1756-A17 Rangka ControlLogix Allen-Bradley

1

/

dari

3

1756-A17 Rangka ControlLogix Allen-Bradley

No reviews

Tersedia (16 unit), siap untuk dikirim

-

Vendor:

Allen-Bradley

-

Tipe:

ControlLogix Chassis

-

Country of Origin:

USA

-

Dimensions:

73.8*16.9*14.5cm

- Weight:

2200 g

- Tag: Controllogix chassis

Allen-Bradley 1756-A17 ControlLogix Chassis

Konfigurasi & Pemasangan Rangka

- Kapasitas Slot Maksimum: Tujuh belas slot total untuk ekspansi sistem yang luas

- Keamanan Pemasangan: Sepuluh tab pemasangan (lima atas, lima bawah) untuk instalasi yang kokoh

- Integrasi Catu Daya: Area pemasangan khusus di sisi kiri terpisah dari slot utama

- Opsi Seri: Tersedia dalam Seri A, B, dan C dengan peningkatan progresif

- Peningkatan Seri C: Panduan slot yang diperbaiki, ventilasi, dan grounding tambahan

Sistem Distribusi Daya

- Backplane Kapasitas Tinggi: Maksimum 15 ampere pada DC 5,1V untuk modul dengan kebutuhan daya tinggi

- Daya Per Slot: Maksimum 6 ampere per slot pada alokasi DC 5,1V

- Dukungan Tegangan Komprehensif: Rel distribusi DC 1,2V, 3,3V, 5,1V, dan 24V

- Manajemen Termal: Disipasi daya maksimum 6W dengan pendinginan yang dioptimalkan

- Operasi Efisien: Konsumsi daya tipikal 1,8W selama operasi normal

Dimensi Fisik & Persyaratan Ruang

- Dimensi Rangka: 738 x 169 x 145 mm (29.06" x 6.65" x 5.71")

- Ukuran Kabinet Minimum: 914 x 762 x 203 mm (36" x 30" x 8")

- Jarak Rangka Bersebelahan: 4,0" sisi kiri ditambah lebar catu daya

- Jarak Sisi Kanan: 3,0" ditambah lebar catu daya untuk akses pemeliharaan

- Jarak Vertikal: 6,0" atas dan 2,0" bawah untuk ventilasi yang tepat

Fitur Sistem Lanjutan

- Pencatatan Waktu Urutan Kejadian: Kemampuan bawaan untuk merekam kejadian kritis

- Dukungan RIUP: Fungsi Pencabutan dan Pemasangan Penuh Saat Daya Hidup

- Penguncian Elektronik: Mencegah kesalahan pemasangan dan penggantian modul

- Diagnostik Komprehensif: Identifikasi kesalahan lanjutan untuk masalah sistem dan sisi lapangan

- Komunikasi Kecepatan Tinggi: Backplane dioptimalkan untuk pertukaran data antar modul yang cepat

Persyaratan Instalasi & Listrik

- Ground Fungsional: Kabel tembaga minimal 8,3 mm² (8 AWG)

- Ground Pelindung: Kabel tembaga minimal 2,1 mm² (14 AWG)

- Spesifikasi Kabel: Isolasi dengan rating 90°C (194°F) atau lebih tinggi diperlukan

- Perangkat Keras Pemasangan: Kompatibel dengan atau tanpa pemasangan sekrup SEM

- Antarmuka Kabel: Memerlukan Bulletin 1492 IFM atau RTB untuk koneksi sisi lapangan

Catu Daya yang Kompatibel

- Model Standar: 1756-PA72, 1756-PB72

- Model Ditingkatkan: 1756-PA75, 1756-PB75, 1756-PC75

- Model Khusus: 1756-PH75 untuk aplikasi kinerja tinggi tertentu

- Kriteria Seleksi: Berdasarkan kebutuhan daya total modul dan kebutuhan redundansi sistem

Skenario Aplikasi

- Pabrik Proses Besar: Kilang, pengolahan kimia, dan pembangkit listrik

- Manufaktur Kompleks: Pabrik otomotif dan manufaktur diskrit besar

- Sistem Infrastruktur: Fasilitas pengolahan air dan sistem transportasi

- Aplikasi Misi-Kritis: Sistem yang memerlukan redundansi dan keandalan maksimum

- Proyek Ekspansi: Sistem otomasi yang berkembang yang memerlukan kapasitas I/O luas

Pertanyaan yang Sering Diajukan

Apa yang membuat 1756-A17 cocok untuk aplikasi skala besar?

- 1756-A17 menyediakan kapasitas ekspansi maksimum dengan 17 slot, menjadikannya ideal untuk sistem kompleks yang memerlukan banyak prosesor, I/O luas, dan modul komunikasi khusus.

Apa saja kemampuan Sequence of Event?

- Fungsi timestamping bawaan memungkinkan pencatatan urutan kejadian secara tepat untuk pemantauan proses kritis dan pemecahan masalah.

Berapa banyak titik pemasangan yang dimiliki chassis besar ini?

- Ini memiliki sepuluh tab pemasangan (lima atas, lima bawah) untuk pemasangan yang aman dari panjang chassis yang diperpanjang.

Jarak apa yang dibutuhkan antara chassis yang berdekatan?

- Berikan ruang 4,0" ditambah lebar catu daya di sisi kiri dan 3,0" ditambah lebar catu daya di sisi kanan untuk akses pemeliharaan yang tepat.

Fitur diagnostik apa saja yang disertakan?

- Diagnostik komprehensif mengidentifikasi kesalahan sistem dan sisi lapangan, sementara penguncian elektronik mencegah kesalahan pemasangan modul.

Apa saja perbaikan Seri C?

- Panduan slot yang ditingkatkan, ventilasi yang diperbaiki, tab pemasangan yang diperkuat, lubang pemasangan tambahan, dan sekrup ground ekstra untuk terminasi panel.

Ukuran kabinet apa yang dibutuhkan?

- Ruang kabinet minimal 36" L x 30" T x 8" D diperlukan untuk menampung chassis dan memberikan akses pemeliharaan yang tepat.

Untuk spesifikasi teknis dan bantuan perencanaan sistem besar, hubungi ahli otomasi kami di: sales@nex-auto.com

Pengiriman Cepat & Andal

Pengiriman cepat ke seluruh dunia

menjaga proyek otomatisasi Anda tepat waktu.

Asli & Terpercaya

Semua komponen 100% asli

menjamin kinerja yang andal untuk sistem Anda.

- Pengiriman Ekspres

- Garansi 12 Bulan

- 30 Hari Pengembalian Mudah

Dukungan Pelanggan

Dapatkan Bantuan Saat Anda Paling Membutuhkannya

Di Sini untuk Membantu Kebutuhan Otomasi Anda

Hubungi kami untuk harga, detail produk, atau bantuan pemesanan — para ahli kami siap membantu.

Ketahui Hak Pengembalian Anda

Anda memiliki waktu 30 hari untuk mengembalikan produk jika tidak memenuhi persyaratan Anda. Lihat kebijakan lengkap untuk detailnya.