Inicio

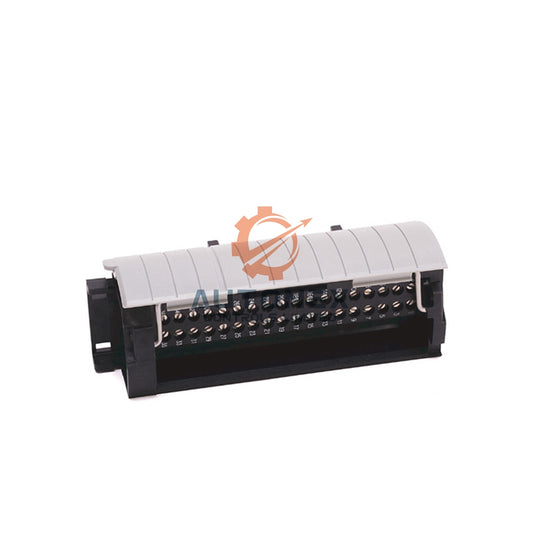

1756-A17 ControlLogix Chassis Allen-Bradley

1

/

de

3

1756-A17 ControlLogix Chassis Allen-Bradley

No reviews

En stock (16 unidades), listo para ser enviado

-

Vendedor:

Allen-Bradley

-

Tipo:

ControlLogix Chassis

-

Country of Origin:

USA

-

Dimensions:

73.8*16.9*14.5cm

- Weight:

2200 g

- Etiquetas: Controllogix chassis

Allen-Bradley 1756-A17 ControlLogix Chassis

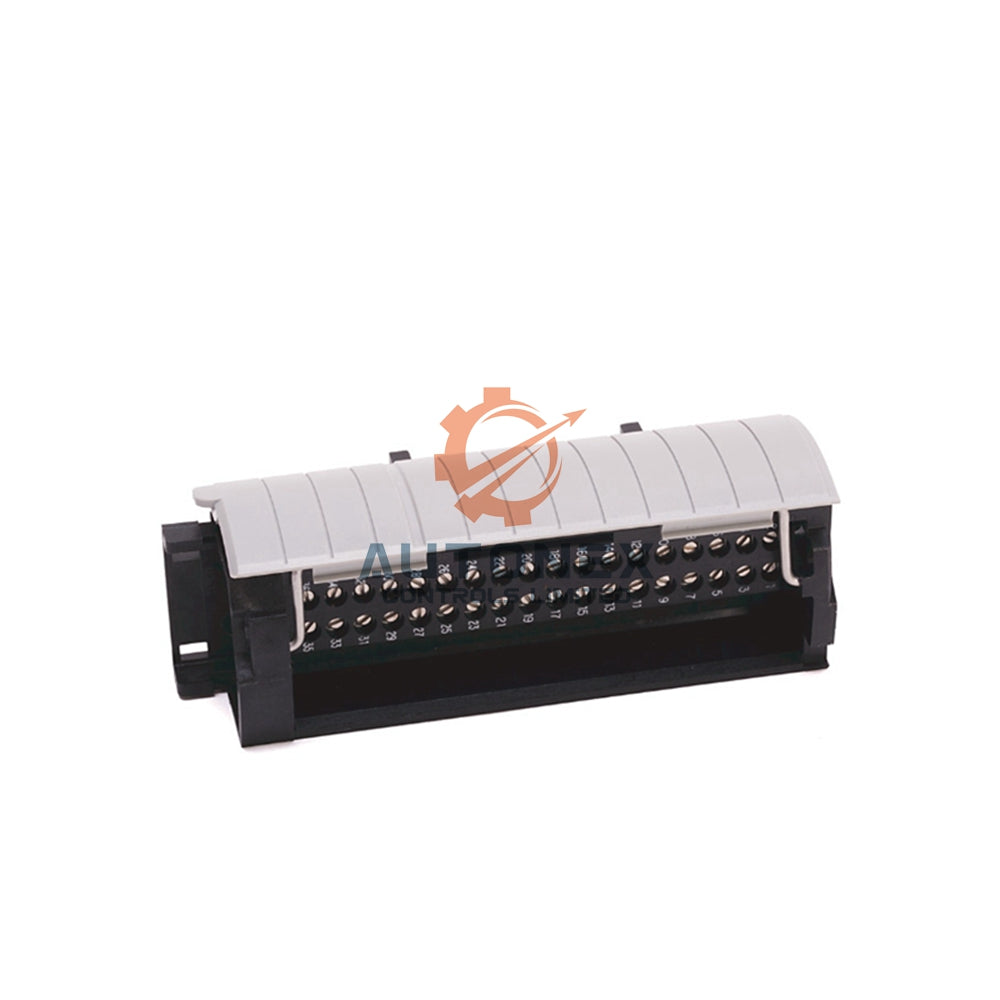

Chassis Configuration & Mounting

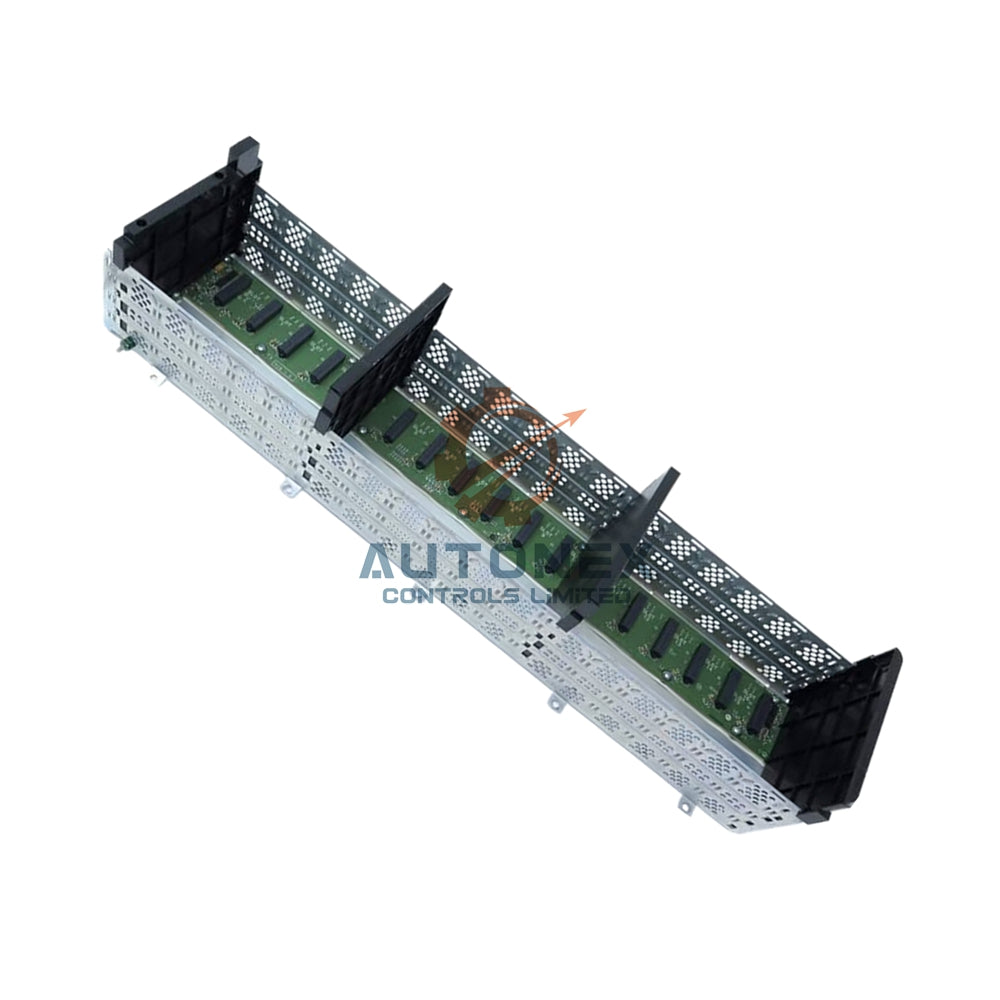

- Maximum Slot Capacity: Seventeen total slots for extensive system expansion

- Mounting Security: Ten mounting tabs (five top, five bottom) for robust installation

- Power Supply Integration: Dedicated left-side mounting area separate from main slots

- Series Options: Available in Series A, B, and C with progressive improvements

- Series C Enhancements: Improved slot guides, ventilation, and additional grounding

Power Distribution System

- High-Capacity Backplane: 15 amps maximum at 5.1V DC for power-intensive modules

- Per-Slot Power: 6 amps maximum per slot at 5.1V DC allocation

- Comprehensive Voltage Support: 1.2V, 3.3V, 5.1V, and 24V DC distribution rails

- Thermal Management: 6W maximum power dissipation with optimized cooling

- Efficient Operation: 1.8W typical power consumption during normal operation

Physical Dimensions & Space Requirements

- Chassis Dimensions: 738 x 169 x 145 mm (29.06" x 6.65" x 5.71")

- Minimum Cabinet Size: 914 x 762 x 203 mm (36" x 30" x 8")

- Adjacent Chassis Clearance: 4.0" left side plus power supply width

- Right Side Clearance: 3.0" plus power supply width for maintenance access

- Vertical Clearance: 6.0" top and 2.0" bottom for proper ventilation

Advanced System Features

- Sequence of Event Timestamping: Built-in capabilities for critical event recording

- RIUP Support: Full Removal and Insertion Under Power functionality

- Electronic Keying: Prevents module installation and replacement errors

- Comprehensive Diagnostics: Advanced fault identification for system and field side issues

- High-Speed Communication: Optimized backplane for fast inter-module data exchange

Installation & Electrical Requirements

- Functional Earth Ground: 8.3 mm² (8 AWG) copper wire minimum

- Protective Earth Ground: 2.1 mm² (14 AWG) copper wire minimum

- Wire Specifications: 90°C (194°F) rated or higher insulation required

- Mounting Hardware: Compatible with or without SEM screws installation

- Wiring Interface: Requires Bulletin 1492 IFM or RTB for field-side connections

Compatible Power Supplies

- Standard Models: 1756-PA72, 1756-PB72

- Enhanced Models: 1756-PA75, 1756-PB75, 1756-PC75

- Specialized Models: 1756-PH75 for specific high-performance applications

- Selection Criteria: Based on total module power requirements and system redundancy needs

Application Scenarios

- Large Process Plants: Refineries, chemical processing, and power generation

- Complex Manufacturing: Automotive plants and large discrete manufacturing

- Infrastructure Systems: Water treatment facilities and transportation systems

- Mission-Critical Applications: Systems requiring maximum redundancy and reliability

- Expansion Projects: Growing automation systems requiring extensive I/O capacity

Frequently Asked Questions

What makes the 1756-A17 suitable for large-scale applications?

- The 1756-A17 provides maximum expansion capacity with 17 slots, making it ideal for complex systems requiring multiple processors, extensive I/O, and specialized communication modules.

What are the Sequence of Event capabilities?

- Built-in timestamping functionality allows precise recording of event sequences for critical process monitoring and troubleshooting.

How many mounting points does this large chassis have?

- It features ten mounting tabs (five top, five bottom) for secure installation of the extended chassis length.

What clearance is needed between adjacent chassis?

- Allow 4.0" plus power supply width on left side and 3.0" plus power supply width on right side for proper maintenance access.

What diagnostic features are included?

- Comprehensive diagnostics identify both system and field-side faults, while electronic keying prevents module installation errors.

What are the Series C improvements?

- Enhanced slot guides, improved ventilation, reinforced mounting tabs, additional mounting holes, and extra ground screw for panel termination.

What cabinet size is required?

- Minimum 36" W x 30" H x 8" D cabinet space is needed to accommodate the chassis and provide proper maintenance access.

For technical specifications and large system planning assistance, contact our automation experts at: sales@nex-auto.com

Envío rápido y fiable

Entrega rápida en todo el mundo

mantiene sus proyectos de automatización en el calendario.

Genuino y Confiable

Todos los componentes son 100% auténticos

asegurando un rendimiento fiable para sus sistemas.

- Entrega Exprés

- 12 Meses de Garantía

- 30 Días Devoluciones Fáciles

Atención al cliente

Obtén ayuda cuando más la necesitas

Aquí para asistir en sus necesidades de automatización

Contáctenos para precios, detalles del producto o asistencia con pedidos — nuestros expertos están disponibles para ayudar.

Conozca Sus Derechos de Devolución

Tienes 30 días para devolver un producto si no cumple con tus requisitos. Consulta la política completa para más detalles.